Sand blasting is when a surface is cleaned or prepared by forcibly propelling a stream of abrasive material against it.

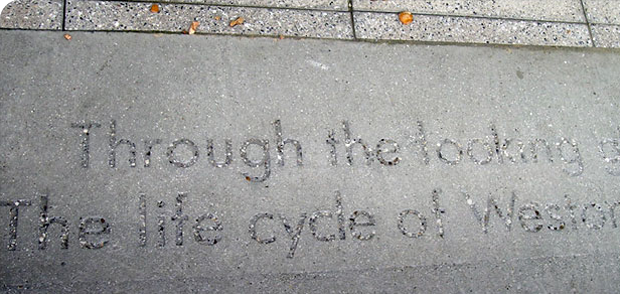

Blast cleaning (sandblasting, grit-blasting) consists of bombarding the surface of a material with one of many types of sand, grit or shot. Normally sandblasting is carried out to remove paint, rust or scale, but sometimes it is required to impart a particular surface, or uniform finish, to the object being blasted.

A typical sandblasting rig consists of a high powered air-compressor connected to a blasting pot (where the sand or grit is introduced) connected via a length of blast hose to the blast nozzle.

The abrasive material used can be calcium silicate, calcium carbonate, granules of iron silicate (chilled iron), silicon carbide, glass grit produced from recycled bottle bank glass, aluminium oxide, garnet and even walnut shells! Abrasive materials are available in many different sizes, from dust to 3.5mm.

Items which can be cleaned by our company vary from wood, soft stone, brick and masonry, through to aluminium, iron and steel. It is “simply” a case of determining the correct material and pressure to accomplish the task. For instance, wood or soft stone would be sandblasted at very low pressure using the finest grade of sand available, whereas iron or steel can be cleaned at full pressure using 2.5mm chilled iron, if necessary. It is advisable to apply a first coat of primer to freshly blasted metal to prevent the onset of corrosion, and this can be carried out by Steadblast using spray, roller or brush.

Dust nuisance can be effectively controlled, where appropriate, by using our Sat-Blast system; abrasive and water are mixed inside the machine and then delivered at pressures as low as 5 psi. As well as being dust-free, this device enables cleaning of delicate soft stone, using powdered abrasives that would otherwise be unsuitable in a traditional sandblasting pot.

If the use of water is not appropriate, we can still blast “dry” at very low pressure and have dust extraction equipment which will remove dust from confined spaces.

Due to the unpredictable nature of this work, and in order to gain an idea of the cost of the cleaning, it is sometimes necessary to carry out a “test patch” on the item in question; to ascertain the amount of time and material that will be required to remove the layers of paint etc without damaging the surface of the item itself.